Materials science ain’t easy. And it’s especially difficult when it comes to the batteries that power our smart home, wearable, and mobile devices; more specifically, lithium-ion (Li-ion) batteries. Enovix is claiming success at CES with the holy grail of Li-ion battery anodes: 100-percent silicon.

But before I dive into what the company says it’s accomplished, let’s get a quick foundation on today’s battery tech.

Why silicon?

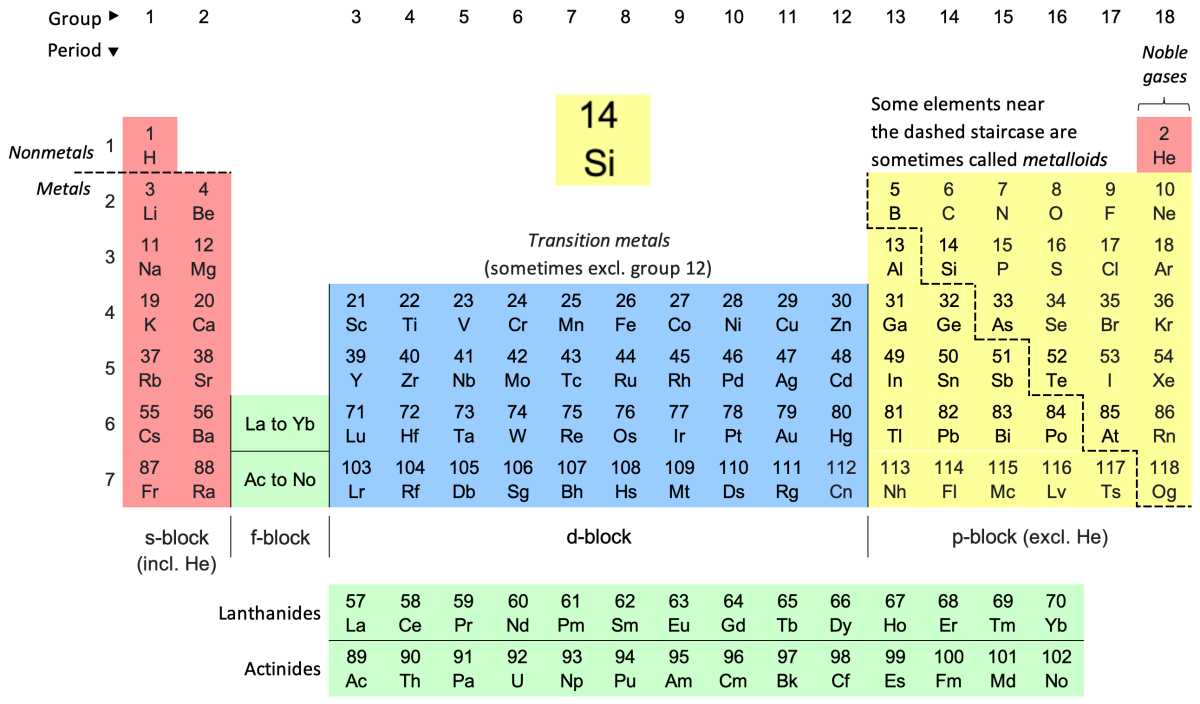

Silicon is an element every manufacturer wants to use. Beyond possessing some very useful properties, such as semi-conductance, it’s environmentally innocuous and extremely plentiful, rendering the material very inexpensive.

In fact, silicon is the second-most abundant element on the planet–behind only oxygen. It’s also geographically ubiquitous, so it can’t be held hostage by any one political or commercial entity, unlike such materials as rare-earth elements.

Enovix

More to the point, one of silicon’s lesser-known desirable properties is that can absorb a whole lot of lithium ions; theoretically, around 10 times the number as graphite, which is the current go-to material for Li-ion battery anodes.

Well, why not silicon?

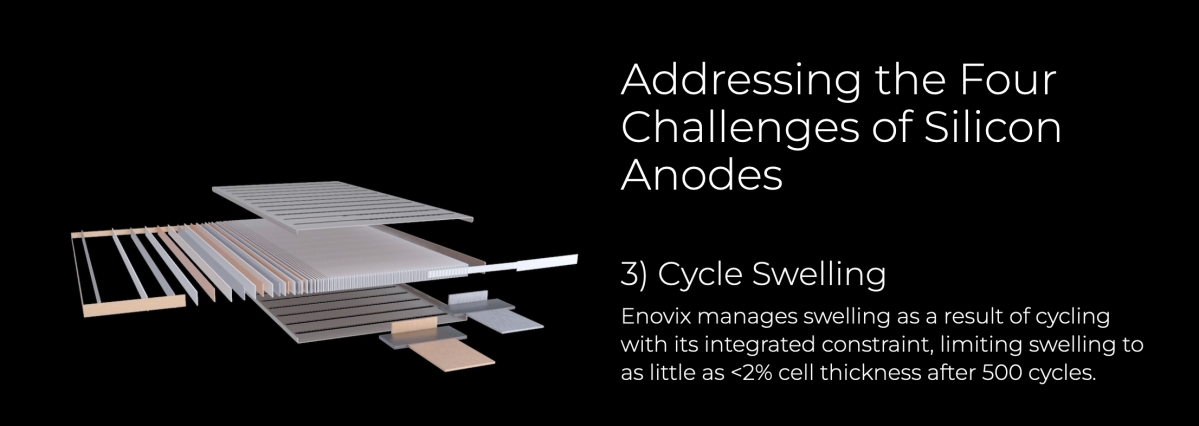

Alas, silicon is so good at absorbing lithium ions (which it does differently than graphite) that it has a distinct tendency to swell as a result of the process. Therein lies the conundrum.

While a silicon-anode Li-ion battery could theoretically offer 10 times the storage capacity of a same-sized graphite-anode Li-ion battery, it would, without constraint, swell far beyond its uncharged size–by as much as three to four times, depending on who you talk to.

A corollary issue during lithiation (a scientific term for sucking up lithium ions) is that swelling at the particle level can also result in cracking and degradation, drastically reducing efficiency over time if left unchecked.

In a nutshell, anyone looking to leverage silicon’s fantastic potential for storing energy must overcome these issues.

Wikipedia

According to Enovix, with a normal jelly-rolled, single-cell Li-ion battery design, constraining the aforementioned silicon swelling would require something along the lines of 1.7 tons of constraining force for a cellphone-sized battery. If you followed the Titan submersible accident, that’s about what it would’ve faced at 10,000 feet, albeit inward instead of outward.

Good luck designing nearly two tons of constraint into your battery structure while keeping its size and weight practical and marketable. The heavier the battery, the more of its stored energy is wasted simply moving it around.

A battery’s useful energy density is generally measured per gram, and rephrased, a 10-fold-per-gram rating for cell materials means little if a massive constraining structure wastes the advantage.

Enovix’s solution

Enovix says that by stacking multiple mini-cells horizontally, they will require only 210 pounds of constraining force for the same cellphone-sized battery. Stacking them crosswise in this manner, as illustrated below, also sends the vast majority of the pressure to the smaller ends of the battery, rather than the larger upper and lower surfaces.

This means the top and bottom of the steel casing can be much thinner than what would otherwise be required, saving a lot of weight. So yes, Enovix hasn’t eliminated swelling, it’s just limited its affect on the battery to 2 percent in total.

It’s not a 10-fold gain, but it’s still great

While Enovix is using a 100-percent silicon anode, the company’s claimed gain in capacity for its batteries is only up to 43 percent in laptops and 65 percent in cell phones; not the theoretical 1,000 percent silicon might otherwise offer. One might guess that this is due to using smaller anodes and the weight of the constraining structure.

Regardless, if this translates to larger car batteries (no density-improvement claims are available for EVs yet), this could mean an EV with 300-mile range could go close to 500 miles between charges. But range is only part of the viable long-range EV equation. Gas vehicles have similarly short ranges, but it takes only 5 to 10 minutes to fill a gas tank, compared to 6 to 10 hours to charge a long-range EV.

Mikael Lindkvist

Alas, Enovix makes no assertions for improvements in charge or discharge rates. The company also told me that the maximum number of recharge cycles currently stands at 500, down a bit from the 800 to 1000 cycles current graphite-anode Li-ion batteries deliver.

On the other hand, the steel structure and overall design of Enovix’s batteries enable them to shed heat faster during fast charging, ameliorating overheating issues during that operation. EVs, of course, make for an easy illustration, because of the road-trip conundrum; but a 43- to 65-percent gain in battery life for your laptop, phone, security cam, smart watch, and other devices would be more than welcome.

How well the technology measures up in terms of weight, size, and useful capacity for other applications, only time will tell. Equally important, Enovix hasn’t indicated how much batteries using its Li-ion-anodes might cost. Whatever the case may be, longer-lived batteries are something we’re all looking forward to.

Editor’s note: All the claims and specs for Enovix’s technology in this article were sourced from the company itself; we have not independently tested any of its products. If this article has sparked an interest in silicon-anode Li-ion batteries, you might want to also look what Amprius is up to.