Samsung Foundry is the second-largest independent foundry in the world after giant TSMC. In other words, besides manufacturing the Exynos chips that it designs itself, Samsung manufactures chips based on the designs submitted by third-party companies that are the foundry’s customers such as Qualcomm.

Samsung Foundry continues to struggle with yield

TSMC ended up receiving orders from Qualcomm to build its remaining Snapdragon 8 Gen1 chipsets along with the Snapdragon 8 Gen 1 Plus SoC. We also assume that TSMC will get the nod to build the 3nm Snapdragon 8 Gen 2 sequel even if Qualcomm will need to pay TSMC a premium to have an exclusive manufacturer for the chipset build enough chips in a short period of time.

Not only is that an extremely low yield, one that Samsung needs to improve, it is worse than the aforementioned 35% yield that Sammy had experienced with the 4nm Snapdragon 8 Gen 1.

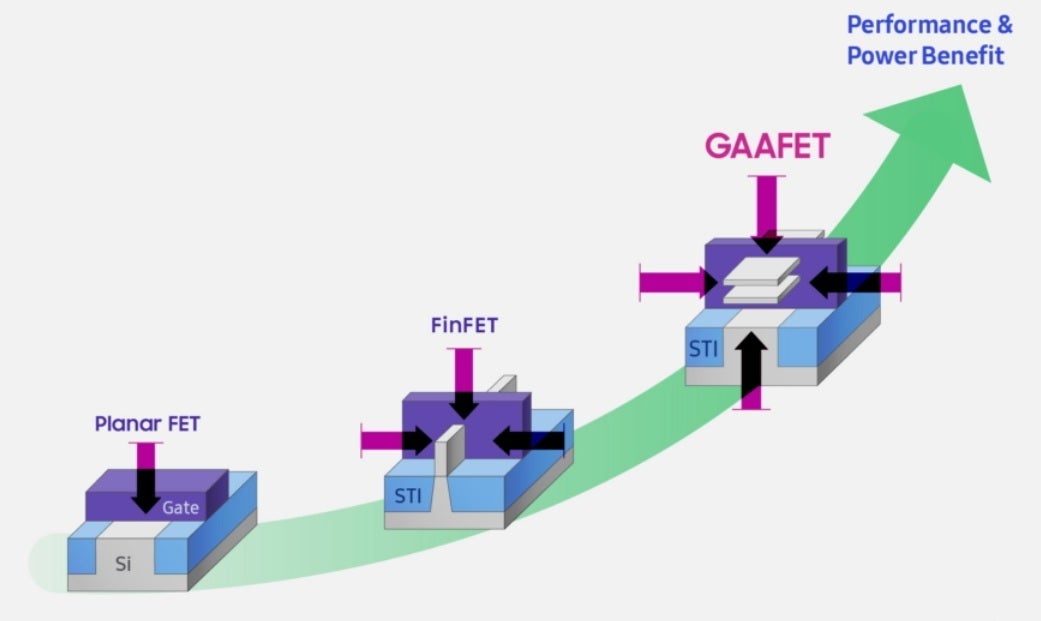

Wccftech says that according to sources, the first “performance version” of its 3nm GAA chipsets that Samsung will ship to customers starting next year could actually be new in-house Exynos chips. Samsung reportedly has been working on a new family of Exynos chips for its smartphones but at this stage, it is unclear whether they will be built using the 3nm GAA process node.

TSMC and Samsung will soon have a new challenger when it comes to process leadership

TSMC and Samsung will soon have a new challenger as Intel has said that it has a goal to take over process leadership in the industry by the end of 2024. It also has first crack at obtaining a more advanced Extreme Ultraviolet (EUV) lithography machine from the leader in EUV, Dutch manufacturer ASML.

By getting its hands on this machine first, Intel will be able to take a huge step toward its goal of reclaiming process leadership from TSMC and Samsung. Each machine costs Intel more than $340 million.